BMS Software Protection Board

BMS Software Board Solution

BMS Software Protection Board | BMS Battery Management Software

A BMS software board is a battery management system implemented on the basis of a software program, which usually includes key components such as a master control unit, a communication module, an algorithm module, and a data storage module. Its main task is to perform advanced functions such as data processing, condition diagnosis and troubleshooting.

KOOM is able to offer customized BMS software board solutions according to specific application areas and requirements. Our BMS software protection boards are suitable for a variety of application scenarios, including mobile energy storage, high-speed electric motorcycles, electric bicycles, and low-speed electric vehicles. Our software protection boards can be used to provide battery protection for 8 to 16 series Li-ion battery systems. In addition, through parameter configuration, our BMS protection boards are suitable for different types of batteries, such as lithium iron phosphate, lithium nickel cobalt manganate and lithium titanate. Our goal is to provide our customers with highly customizable solutions that meet their specific needs.

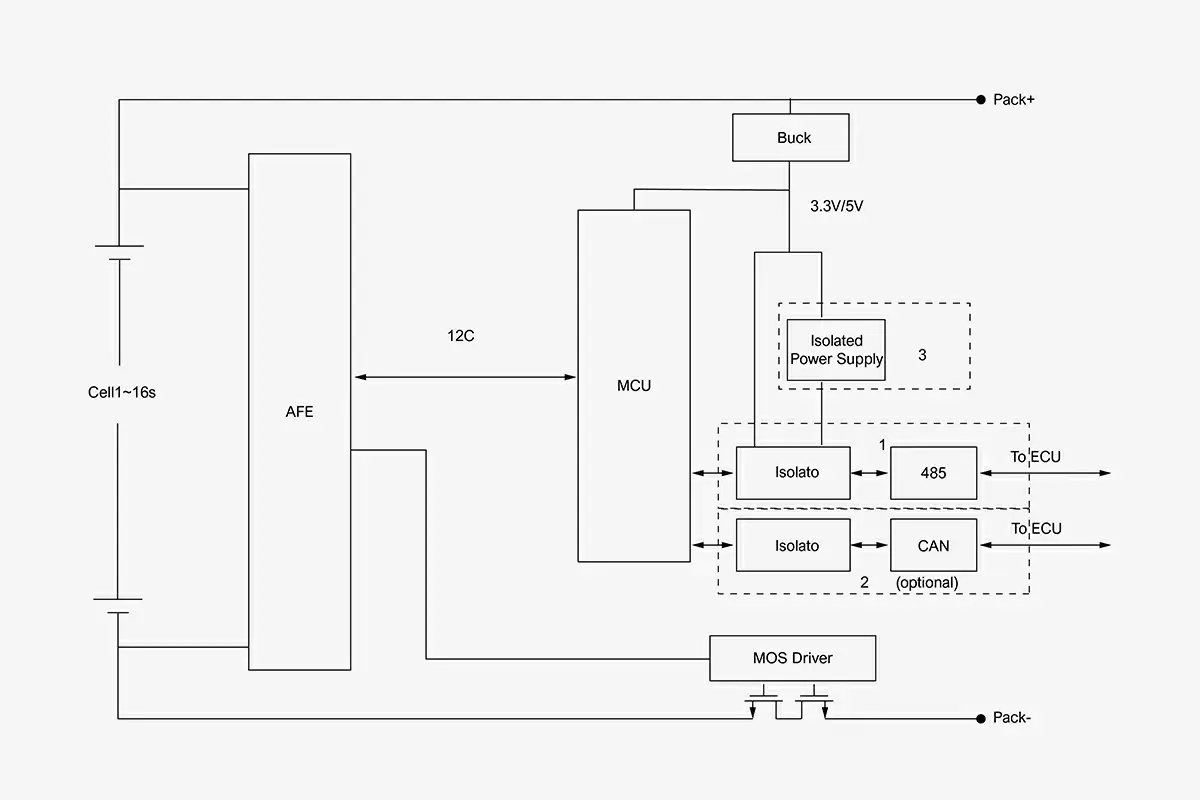

BMS Software Board Schematic Diagram

Features

Powerful Functionality

- It utilizes digital front-end chips and proprietary SOC & SOH algorithms, enabling highly accurate SOC estimation for battery packs.

- Real-time monitoring of voltage, current, temperature, and other vital information.

Strong Expandability

- Supports three communication modes: 485 serial port, CAN, and optional Bluetooth. It also supports data monitoring through an optional APP mini-program.

- Flexibility in adjustment and upgrade through software updates and extensions.

Perfect Compatibility

- Utilizes self-developed core chips, and the core components are directly supplied by original manufacturers, ensuring stable quality control and high compatibility.

- The backend system is developed and maintained in-house, providing timely responses and low maintenance costs.

What Services Do We Provide?

PCBA Development

Carefully select the most suitable performance and cost solutions based on customer requirements, completing a series of comprehensive processes including schematic design, PCB layout, board assembly and testing, PCBA acceptance, and summary reports.

Appearance Design

Capture various design inspirations, sketches, hand models, or textual descriptions from customers, maximizing the recreation of their envisioned appearance and adding visual innovations for better market acceptance.

Personalized Customization

Referencing customer samples or panel drawings, plan various parameters and special features to meet personalized customization requirements. Also provide Original Design Manufacturer (ODM) production, customized system UI interfaces, and more.

Proofing Support

Based on customer-provided drawings and requirements, complete sample component procurement, sample prototyping, and sample testing within 7 working days, delivering them to customers for testing and evaluation.

Technical Support

Provide professional technical consultation and direct support services, covering development design, sample testing, system maintenance, and more, to shorten product development cycles and reduce customer operating costs.

Supply Chain Support

Utilize a well-established supply chain system to offer customers comprehensive PCBA solutions, battery solutions, and module solutions, significantly improving assembly efficiency and enabling fast delivery.

FAQs

The BMS software protection board includes essential features such as state-of-charge (SoC) estimation, cell voltage monitoring, temperature monitoring, current sensing, and fault detection. These software functionalities enable accurate battery monitoring, protection, and control to ensure safe and optimal operation.

The BMS software protection board utilizes advanced algorithms, such as the Coulomb counting method or Kalman filters, to estimate the battery’s state of charge (SoC) and state of health (SoH). By analyzing voltage, current, and temperature data, the BMS software can predict battery performance and provide accurate information about remaining capacity and expected battery life.

Yes, the BMS software protection board can be customized to meet specific customer requirements. The software can be tailored to support different battery chemistries, pack configurations, and communication protocols. Customization allows for seamless integration with existing systems and the ability to adapt to unique application needs.

The BMS software protection board incorporates comprehensive fault detection mechanisms, including abnormal voltage, current, and temperature readings. When anomalies are detected, the software triggers appropriate actions such as isolating faulty cells, activating alarms, or initiating a safe shutdown to prevent further damage and ensure battery safety.

The BMS software protection board supports various communication protocols, such as CAN (Controller Area Network) or Modbus, enabling seamless data exchange with external devices and systems. This allows for remote monitoring, real-time data analysis, and integration with energy management systems, chargers, or other control systems.