Battery Management System

BMS Solution Provider

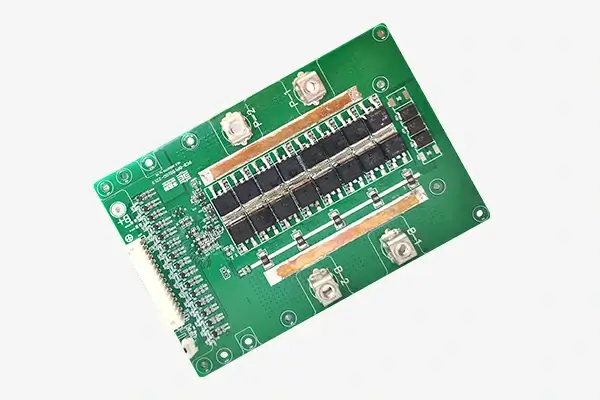

We provide BMS hardware solution boards that include functions such as overcharge protection, over-discharge protection, overcurrent protection, short circuit protection, and temperature control protection. Based on the product application, we reasonably solidify relevant technical parameters to ensure the reliability and safety of the battery.

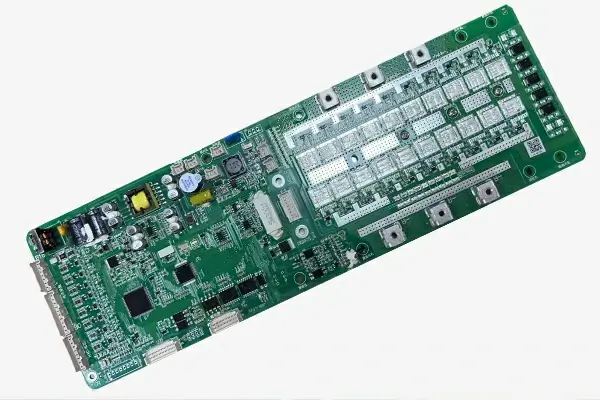

We provide BMS software board solutions that, in addition to the hardware protection board, offer functional expansion and adjustable parameters. These software boards allow communication with the application end and execution of instructions, enabling more reasonable adjustment, optimization, maintenance, and monitoring of the battery status.

BMS Industry Solutions

BMS, short for Battery Management System, is an integrated system designed to provide comprehensive management and protection for battery packs. It integrates components such as battery management chips, sensors, fuses, communication interfaces, and software algorithms. By performing real-time monitoring, state evaluation, charge-discharge control, and fault protection functions, it enables full management of the battery.

As a professional BMS manufacturer and solution provider, KOOM focuses on custom hardware BMS and software BMS solutions to meet the battery management needs and industry standards in areas such as home energy storage, mobile energy storage, electric bicycles, electric tricycles, electric forklifts, and electric golf carts.

KOOM has an experienced automotive-grade BMS R&D team, and its BMS servers are located in the United Kingdom, providing services to global users. As of May 2023, KOOM has already served over 93,000 users in the European and American markets.

BMS Product Features

Remote OTC

- Supports remote assistance, remote monitoring, proactive fault reporting, remote protocol matching, remote diagnostics, etc

- Removes spatial distance limitations and lowers after-sales maintenance costs

- Provides a better end-user experience, efficiently and securely protecting the battery

Automotive-grade Team

- Possesses the most advanced software algorithms nationwide

- Has years of experience and technical expertise in developing automotive-grade BMS

- Capable of independently matching various grades of battery cells with different quality levels

BMS Solution Application

Home Energy Storage

Home Energy Storage includes energy storage systems such as lithium-ion batteries, lead-acid batteries, and supercapacitors. It enables end-users to achieve energy efficiency and environmental friendliness while ensuring the safety and reliability of the batteries, effectively enhancing user experience and reducing concerns.

Mobile Energy Storage

Mobile Energy Storage involves power generation from sources like electricity, solar energy, wind energy, or other renewable energy sources. It finds wide applications in top-tier enterprises, primarily known for its stable power output and input, low heat emissions, and other notable features.

Small Electric Vehicle

Small Electric Vehicle encompasses electric bicycles, electric tricycles, electric forklifts, and electric golf carts. By leveraging appropriate ruggedization processes and advanced algorithms, batteries in these vehicles remain durable and long-lasting even in harsh environments and under frequent charge/discharge cycles.

BMS Technical Features

Integration of Science and Education

Koom maintains a close partnership with Xi’an University of Electronic Science and Technology and Xi’an Jiaotong-Liverpool University. This collaboration includes the establishment of joint laboratories and the translation of research outcomes into practical project development.

Technological Breakthroughs

Koom actively pursues breakthroughs in technology, encompassing research in new materials, processes, and methods. Particularly in the field of Battery Management Systems (BMS), they are committed to innovative advancements in algorithms and processes.

What Services Do We Provide?

PCBA Development

Carefully select the most suitable performance and cost solutions based on customer requirements, completing a series of comprehensive processes including schematic design, PCB layout, board assembly and testing, PCBA acceptance, and summary reports.

Appearance Design

Capture various design inspirations, sketches, hand models, or textual descriptions from customers, maximizing the recreation of their envisioned appearance and adding visual innovations for better market acceptance.

Personalized Customization

Referencing customer samples or panel drawings, plan various parameters and special features to meet personalized customization requirements. Also provide Original Design Manufacturer (ODM) production, customized system UI interfaces, and more.

Proofing Support

Based on customer-provided drawings and requirements, complete sample component procurement, sample prototyping, and sample testing within 7 working days, delivering them to customers for testing and evaluation.

Technical Support

Provide professional technical consultation and direct support services, covering development design, sample testing, system maintenance, and more, to shorten product development cycles and reduce customer operating costs.

Supply Chain Support

Utilize a well-established supply chain system to offer customers comprehensive PCBA solutions, battery solutions, and module solutions, significantly improving assembly efficiency and enabling fast delivery.

FAQs

BMS is the abbreviation of Battery Management System. It is a system for monitoring, managing, and protecting batteries, commonly used in lithium batteries, electric vehicle batteries, solar energy storage systems, and other battery applications.

The BMS system has the following main functions and functions: battery monitoring, equalizing charging, overcharge and over-discharge protection, temperature control, communication and data recording, security, etc.

The solution architecture of a BMS (battery management system) can vary depending on the application and battery type, but it usually includes the two key parts of a sensor and a monitoring unit and a control unit.

The benefit of our BMS solutions is that they help improve battery performance, reduce operation and maintenance costs, and while improving user experience, they also have a positive effect on environmental protection.