BMS Hardware Protection Board

BMS Hardware Board Solution

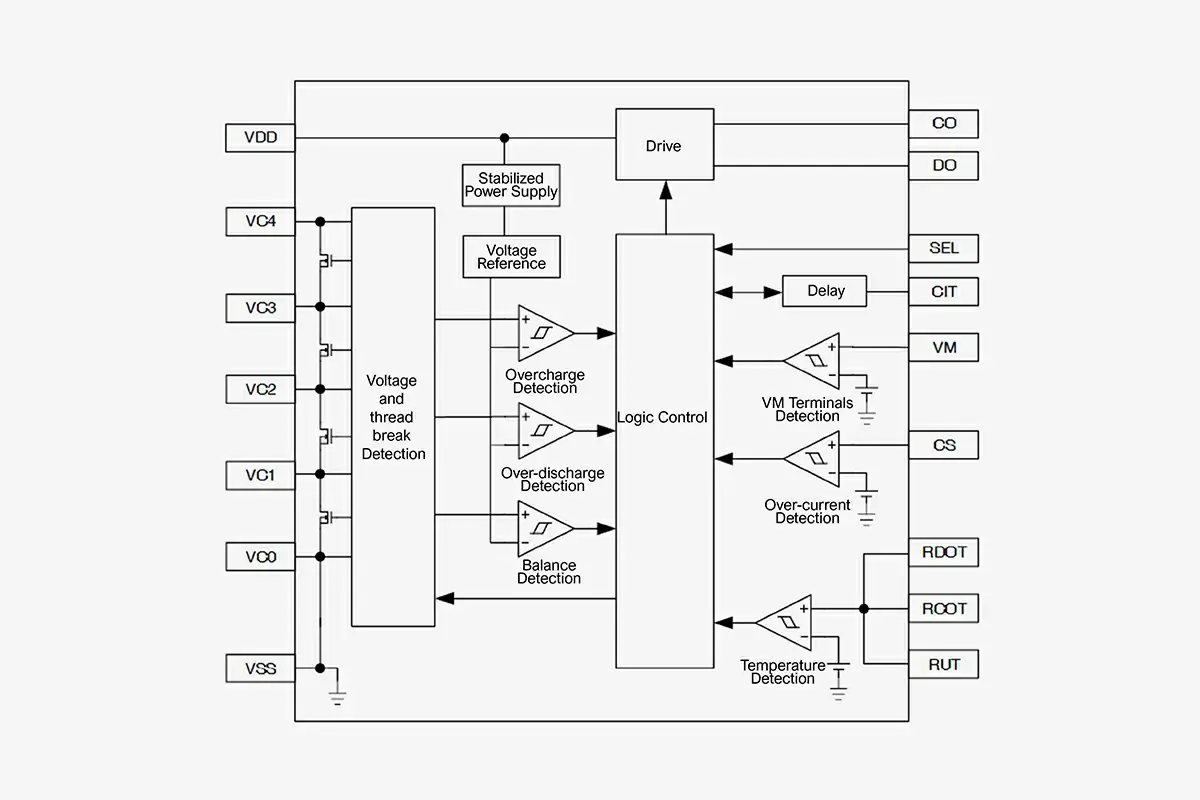

BMS Hardware Design | BMS Hardware Function Overview | BMS Hardware Chips

A BMS (Battery Management System) hardware solution is an implementation of a battery management system using hardware components, typically including sensors, controllers, protectors, balancers, and other hardware elements. Its main task is to achieve multiple functions at the hardware level, such as data acquisition, including battery voltage, current, and temperature; battery protection to ensure the battery’s safety; battery balancing control to maintain consistent states of individual battery cells; and overall battery control, among others.

KOOM Company is able to provide cost-effective hardware BMS solutions based on customers’ personalized needs. These customized solutions can be used in mobile energy storage and home energy storage systems, helping customers improve energy management efficiency and energy utilization efficiency to meet different battery management requirements.

BMS Circuit Schematic Diagram

Features

Perfect Component Matching

- The core chip is developed in-house, and the core components are directly supplied by original manufacturers, ensuring stable quality control and high compatibility.

Outstanding Reliability

- Professionally designed and thoroughly validated through complete simulation to ensure excellent stability.

- Adheres to strict production processes to guarantee high reliability of the product.

Comprehensive Functionality

- Equipped with patented voltage and current monitoring, overcharge and over-discharge alert, and protection functions.

- It includes balancing, temperature monitoring, standby sleep mode, and temperature alert/protection for charging and discharging.

What Services Do We Provide?

PCBA Development

Carefully select the most suitable performance and cost solutions based on customer requirements, completing a series of comprehensive processes including schematic design, PCB layout, board assembly and testing, PCBA acceptance, and summary reports.

Appearance Design

Capture various design inspirations, sketches, hand models, or textual descriptions from customers, maximizing the recreation of their envisioned appearance and adding visual innovations for better market acceptance.

Personalized Customization

Referencing customer samples or panel drawings, plan various parameters and special features to meet personalized customization requirements. Also provide Original Design Manufacturer (ODM) production, customized system UI interfaces, and more.

Proofing Support

Based on customer-provided drawings and requirements, complete sample component procurement, sample prototyping, and sample testing within 7 working days, delivering them to customers for testing and evaluation.

Technical Support

Provide professional technical consultation and direct support services, covering development design, sample testing, system maintenance, and more, to shorten product development cycles and reduce customer operating costs.

Supply Chain Support

Utilize a well-established supply chain system to offer customers comprehensive PCBA solutions, battery solutions, and module solutions, significantly improving assembly efficiency and enabling fast delivery.

FAQs

The BMS hardware protection board incorporates high-precision sensors, such as voltage and current sensors, to accurately monitor the battery’s parameters. These sensors provide real-time feedback to the BMS, enabling precise monitoring and control of the battery pack’s performance. Additionally, advanced analog-to-digital converters (ADCs) and signal processing algorithms ensure reliable and accurate data acquisition.

The BMS hardware protection board offers various safety features, including overvoltage protection, undervoltage protection, overcurrent protection, and overtemperature protection. These protection mechanisms actively monitor and regulate the battery’s operating conditions to prevent potential hazards and ensure safe operation.

Yes, the BMS hardware protection board can be designed to handle high-power applications. By selecting robust components, such as high-current relays, fuses, and MOSFETs, the BMS hardware protection board can effectively manage and distribute high currents while ensuring optimal performance and system reliability.

Yes, modern BMS hardware protection boards often incorporate communication interfaces, such as CAN (Controller Area Network) or RS485, to facilitate data monitoring and analysis. These interfaces allow seamless integration with external devices and systems, enabling real-time data transmission, remote monitoring, and comprehensive analysis of battery performance.

The BMS hardware protection board employs sophisticated cell balancing algorithms and dedicated balancing circuits to ensure the uniform distribution of charge among battery cells. This helps maintain consistent cell voltages, maximize battery capacity utilization, and extend the overall lifespan of the battery pack.