Disposable Vape

PCBA Solution

Disposable Vape PCBA Solution

Disposable Electronic Vigarettes Chip | Mouthpiece | Circuit Board

More than 90% of electronic cigarettes worldwide are produced in China, which has also driven the development of the entire domestic electronic cigarette industry chain.

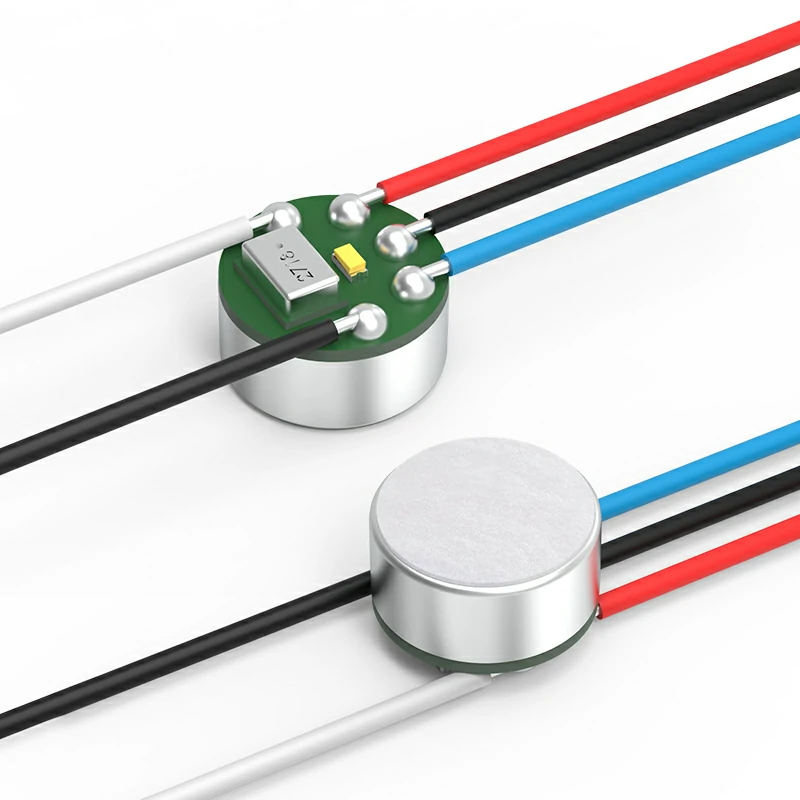

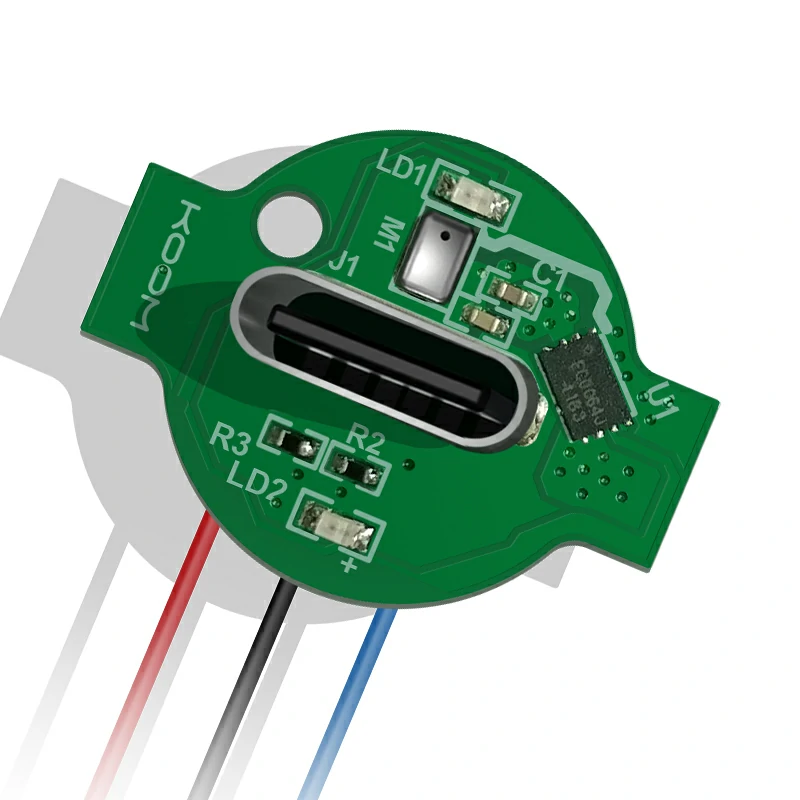

The most common type of electronic cigarette is the disposable one, which adopts ASIC (Application-Specific Integrated Circuit) solutions due to the restrictions on e-liquid capacity imposed by many countries (usually within 2ml) and the pursuit of cost-effectiveness. Disposable electronic cigarette chips, disposable electronic cigarette mouthpieces, and disposable electronic cigarette circuit boards are essential components of such products. These disposable electronic cigarette products typically prioritize basic smoking functionality, thus holding the largest market share.

As a seasoned electronic cigarette solution provider, KOOM developed the first electronic cigarette PMU for a well-known brand as early as 2009. Since then, KOOM has developed various EGO electronic cigarette chips and SOC chips, successfully applying multiple mature ASIC solutions, including disposable electronic cigarette chips, disposable electronic cigarette mouthpieces, and disposable electronic cigarette circuit boards, to meet market demands and secure a certain market share.

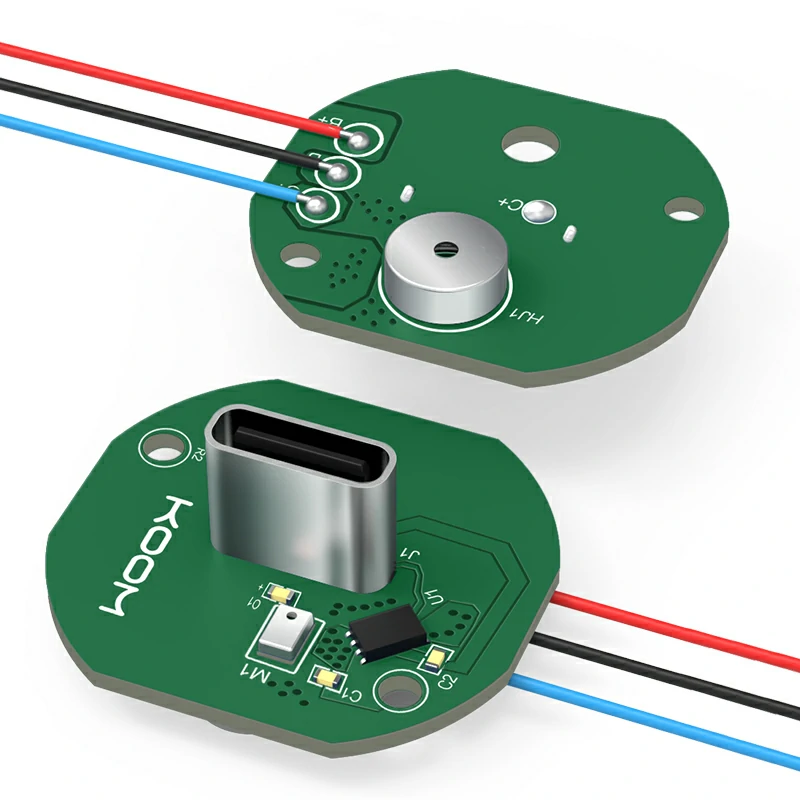

As the core control component of disposable electronic cigarette equipment, the PCBA solution board can realize multiple functions such as power adjustment, mode switching, temperature control, and power management. We can configure the most suitable smart solution according to customers’ different needs for disposable e-cigarette products.

Disposable E-cigarette Solution Features

KOOM Solution VS Traditional Solution

MEMS airflow sensing technology

| KOOM company | Other company |

|---|---|

| √ Utilizing MEMS technology with inverse logic and switch-like arched diaphragm | × Using composite material organic films as capacitive sensing membranes |

| √ Natural resistance to oil and smoke, offering clearer, more reliable, and stable airflow triggering threshold | × Poor consistency in triggering pressure, low resistance to oil and smoke, which can lead to performance degradation, altered taste, and even self-ignition issues |

ASIC wafer level packaging

| KOOM company | Other company |

|---|---|

| √ ASIC packaged with wafer-level HRP (High-Resistivity Package), enabling size reduction and improved assembly efficiency | × Susceptible to environmental pressure changes or transportation vibrations, potentially resulting in self-ignition problems |

| √ Reduced conduction resistance, enhanced heat dissipation, thereby improving chip reliability | × Manual soldering is required during assembly, making it difficult to achieve automated mass production |

What Services Do We Provide?

PCBA Development

Carefully select the most suitable performance and cost solutions based on customer requirements, completing a series of comprehensive processes including schematic design, PCB layout, board assembly and testing, PCBA acceptance, and summary reports.

Appearance Design

Capture various design inspirations, sketches, hand models, or textual descriptions from customers, maximizing the recreation of their envisioned appearance and adding visual innovations for better market acceptance.

Personalized Customization

Referencing customer samples or panel drawings, plan various parameters and special features to meet personalized customization requirements. Also provide Original Design Manufacturer (ODM) production, customized system UI interfaces, and more.

Proofing Support

Based on customer-provided drawings and requirements, complete sample component procurement, sample prototyping, and sample testing within 7 working days, delivering them to customers for testing and evaluation.

Technical Support

Provide professional technical consultation and direct support services, covering development design, sample testing, system maintenance, and more, to shorten product development cycles and reduce customer operating costs.

Supply Chain Support

Utilize a well-established supply chain system to offer customers comprehensive PCBA solutions, battery solutions, and module solutions, significantly improving assembly efficiency and enabling fast delivery.

FAQs

As a provider of disposable electronic cigarette solution boards, we prioritize quality and reliability. We ensure that our products meet the required quality standards, including battery life, stability of heating elements, and reliability of control circuits. We are committed to providing reliable disposable electronic cigarette solutions. We ensure that the disposable electronic cigarette solution does not have safety issues such as overheating, short circuits, or low voltage, to ensure a safe user experience.

The recyclability and sustainability of disposable electronic cigarette solutions depend on the specific product design. We strive to use recyclable materials, reduce energy consumption, and promote sustainable development.

The disposable electronic cigarette mouthpiece typically contains one or more specific chips to control and monitor the smoking experience. Our self-developed ASIC (Application-Specific Integrated Circuit) high-integration electronic cigarette chip integrates core functions such as triggering the heating element, monitoring smoking behavior, and managing power, ensuring the legality and safety of the product.

A short circuit in the disposable electronic cigarette mouthpiece is a possible issue that can prevent the electronic cigarette from functioning properly or pose potential risks. If you encounter a short circuit issue with the electronic cigarette mouthpiece, you can check the connections, replace the mouthpiece, clean the mouthpiece, or consult our after-sales advisors.