Modules Solutions

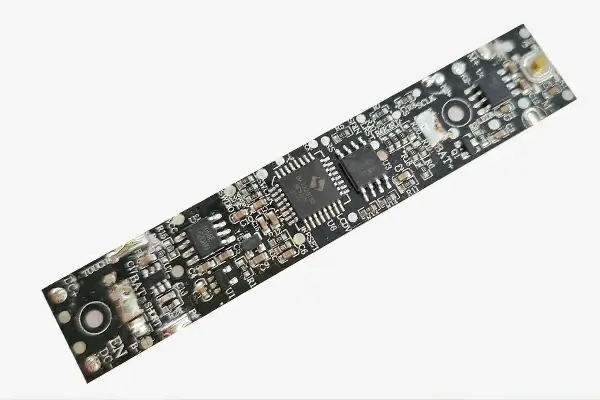

Modules Solutions PCBA Products

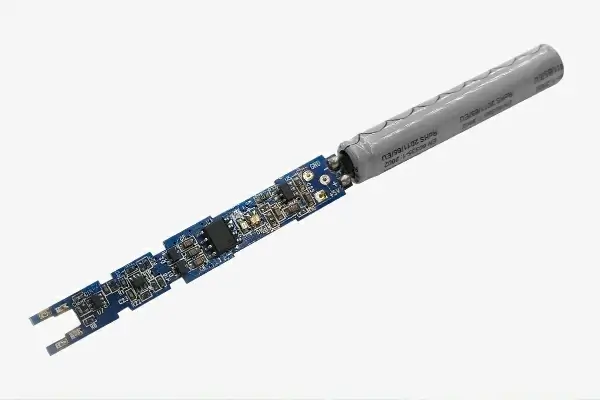

The module provides an electronic cigarette module (HCP) composed of a mouthpiece, solution board, battery cells, and wires, serving as the control center of the vaping device to ensure proper device operation, user safety, and desired smoking experience.

The module offers an innovative HCP module-based solution for capacitor pens, integrating capacitor sensing, drive current, and capacitance detection into a single chip, resolving space and battery capacity limitations in traditional PCBA solutions.

The module provides a lightweight “POWER+ electric toothbrush control module” solution, compatible with various types of electric toothbrush micro-motors, reducing assembly steps and effectively saving production costs domestically and internationally.

The module provides a detachable and recyclable capacitor lithium battery, which can be integrated with Kongke’s self-developed chip and sensor into the HCP module, enabling automation in the production and assembly of consumer electronics products.

Modules Solutions Capacity

In recent years, lean manufacturing and cost-effectiveness have become key objectives for many manufacturing companies. Consumer demands for simplicity, slimness, and portability in electronic products are increasing, yet many products still remain at a low level of automation and limited integration of core components.

KOOM, with its strong R&D team and supply chain integration capabilities, adopts a modular assembly approach in various consumer electronic product fields, integrating the materials that can be integrated in the industry chain into a single module, replacing the originally complex multi-component assembly process. This allows us to achieve simpler assembly and higher levels of production automation, reducing reliance on manual hand soldering assembly and significantly improving product precision. This approach also opens up more possibilities for electronic products with high requirements for product size.

Modules PCBA Products Features

KOOM Solution VS Traditional Solution

● KOOM product

- Integrate the modular components into smaller units

- Achieve smaller internal volume, lower cost, and simpler assembly

● Other product

- Utilize various components for soldering and stacking

- High labor costs, manufacturing complexity, and challenges in quality control

Modules PCBA Application

The application of module solutions covers various consumer electronic products, especially those with significant integration space. This includes but is not limited to products such as electronic cigarettes, electric toothbrushes, and capacitor pens.

Our customized solution capability enables us to provide unique solutions that align with our customers’ product visions, allowing their products to stand out in the market.

What Services Do We Provide?

PCBA Development

Carefully select the most suitable performance and cost solutions based on customer requirements, completing a series of comprehensive processes including schematic design, PCB layout, board assembly and testing, PCBA acceptance, and summary reports.

Appearance Design

Capture various design inspirations, sketches, hand models, or textual descriptions from customers, maximizing the recreation of their envisioned appearance and adding visual innovations for better market acceptance.

Personalized Customization

Referencing customer samples or panel drawings, plan various parameters and special features to meet personalized customization requirements. Also provide Original Design Manufacturer (ODM) production, customized system UI interfaces, and more.

Proofing Support

Based on customer-provided drawings and requirements, complete sample component procurement, sample prototyping, and sample testing within 7 working days, delivering them to customers for testing and evaluation.

Technical Support

Provide professional technical consultation and direct support services, covering development design, sample testing, system maintenance, and more, to shorten product development cycles and reduce customer operating costs.

Supply Chain Support

Utilize a well-established supply chain system to offer customers comprehensive PCBA solutions, battery solutions, and module solutions, significantly improving assembly efficiency and enabling fast delivery.

FAQs

Capacitor pens typically employ capacitive touch technology, which is based on the principle of capacitance. It utilizes the sensing of the body’s charge to achieve touch input on screens or surfaces. We utilize an innovative HCP module-based solution for capacitor pens. Leveraging wafer-level chip packaging technology and excellent chip integration design capabilities, we integrate the three performance modules of capacitive sensing, drive current, and capacitance detection into a single chip. This not only greatly reduces the required space but also makes it compatible with various types of pressure sensors for capacitor pens.

The electric toothbrush circuit board typically includes various components to enable functions such as vibration, power management, charging, and user interaction. Some examples include microcontrollers, vibration motors, power management circuits, batteries, charging circuits, sensors, LED indicators, buttons/switches, capacitive touch sensors, gyroscopes, and accelerometers. Our core components are either self-produced by our parent company or directly sourced from original manufacturers.

A capacitor lithium battery, also known as a supercapacitor or ultracapacitor, is a different energy storage technology from traditional lithium-ion batteries. Our cylindrical capacitor-type cells offer features such as fast charging and discharging, long lifespan, low energy density, suitability for short-term energy storage, and simple assembly.