Specifications

| Symbol | Parameter | Conditions | Minimum | Typical | Maximum | Unit |

|---|---|---|---|---|---|---|

| P | Operating Pressure | – | -150 | – | -250 | Pa |

| Rload | Output Load | – | – | 0.8 | – | Ω |

| Vdd | Operating Voltage Range | – | 2.1 | – | 5.0 | V |

| Iq | Quiescent Current | – | – | 3 | 5 | uA |

| RDS(ON) | Discharge Path On-Resistance | VDD=3.7V | – | 70 | – | mΩ |

| ILED | LED Current to Ground | 2.7V≤VDD≤4.1V | – | 4.2 | – | mA |

| ICHARGE | Charging Current | 2.7V≤VDD≤4.1V VDD≤2.7V |

– – |

550 70 |

– – |

mA mA |

| TSD | Overtemperature Protection Threshold | During Charging During Discharging |

75 140 |

85 150 |

95 160 |

°C °C |

Test Items and Test Conditions

| Test Items | Test Condition |

|---|---|

| Reflow soldering test | Referring to the reflow soldering oven temperature profile, cycle 5 times. |

| Low-temperature test | 168 hours, -40±3℃, IEC 60068-2-1. |

| High-temperature test | 168 hours, 105±3℃, IEC 60068-2-2. |

| Temperature shock test | -40℃, 15 minutes to 125℃, 15 minutes cycle 10 times, IEC 60068-2-4. |

| Constant temperature and humidity test | 168 hours, 85℃/85%, JESD 22-A101A-B. |

| Drop test | 1.8m, 1/3/6-sided drop onto a marble floor, IEC 60068-2-32. |

| ESD-HBM (Electrostatic Discharge – Human Body Model) | ±3KV direct contact discharge to 1/0 pin, MIL 883E, Method 3015.7. |

Features

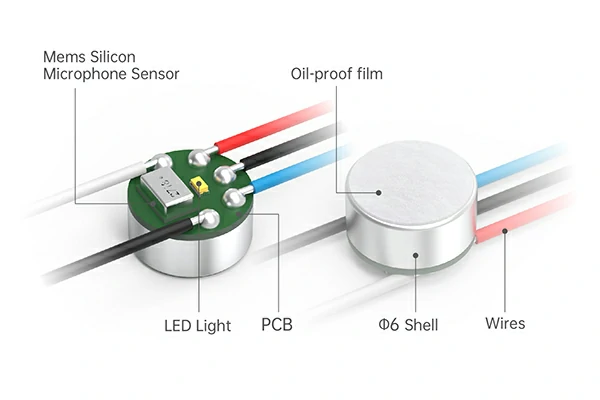

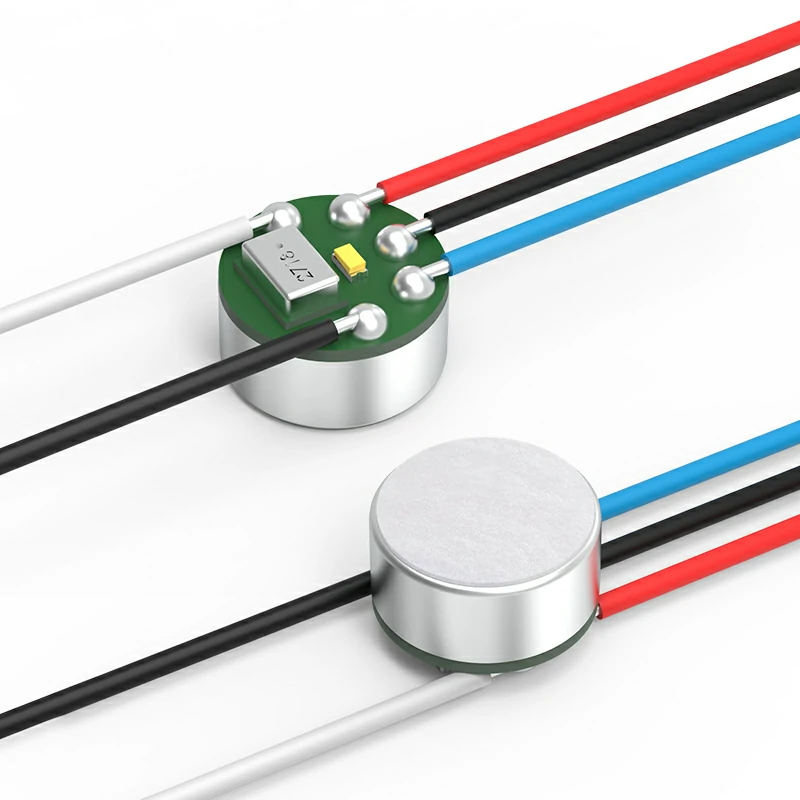

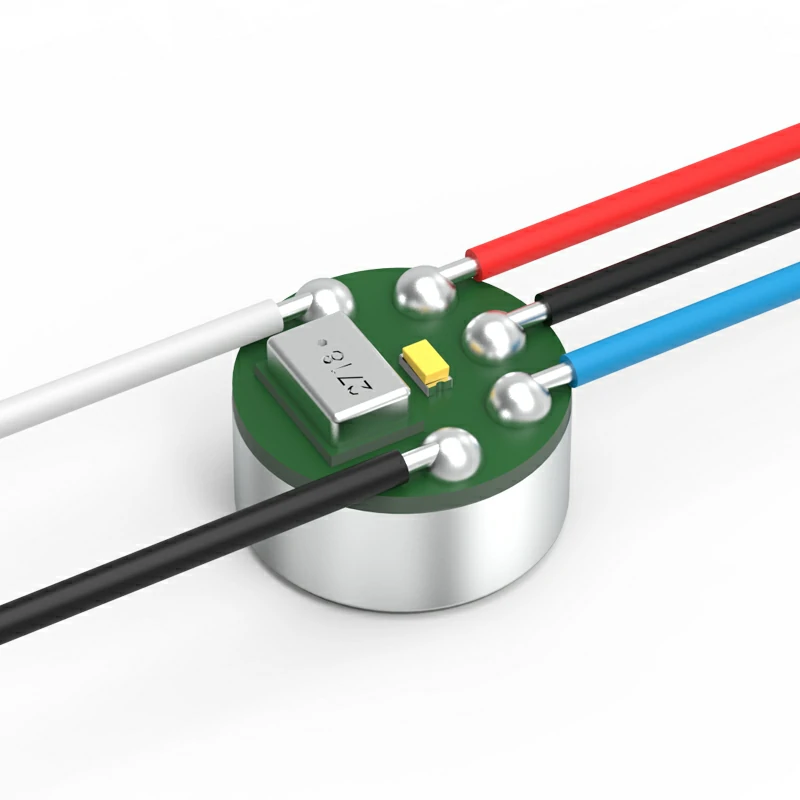

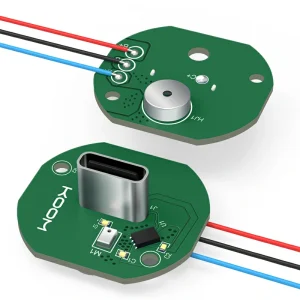

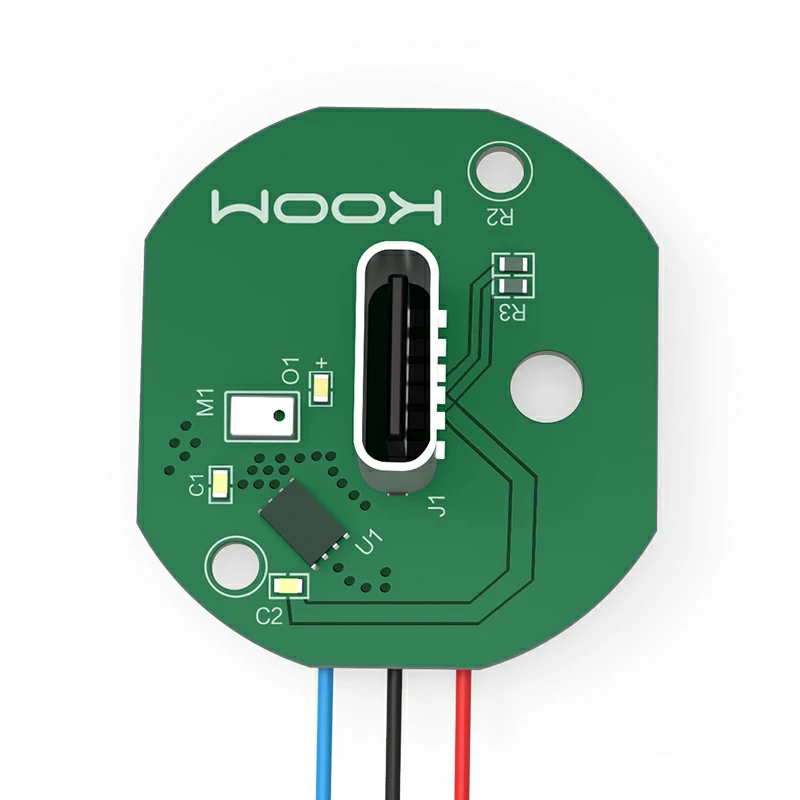

(1) MEMS Silicon Microphone Airflow Sensor:

- Utilizes a unique patented design that allows it to continue functioning normally even when submerged in e-liquid for extended periods of time.

- Has undergone the industry’s longest reliability verification with 100,000 switch cycles, maintaining consistent startup pressure within the range of -15Pa and possessing anti-blow capabilities.

- Capable of detecting inhalation actions of at least 50 puffs, ensuring an extremely long lifespan and excellent stability.

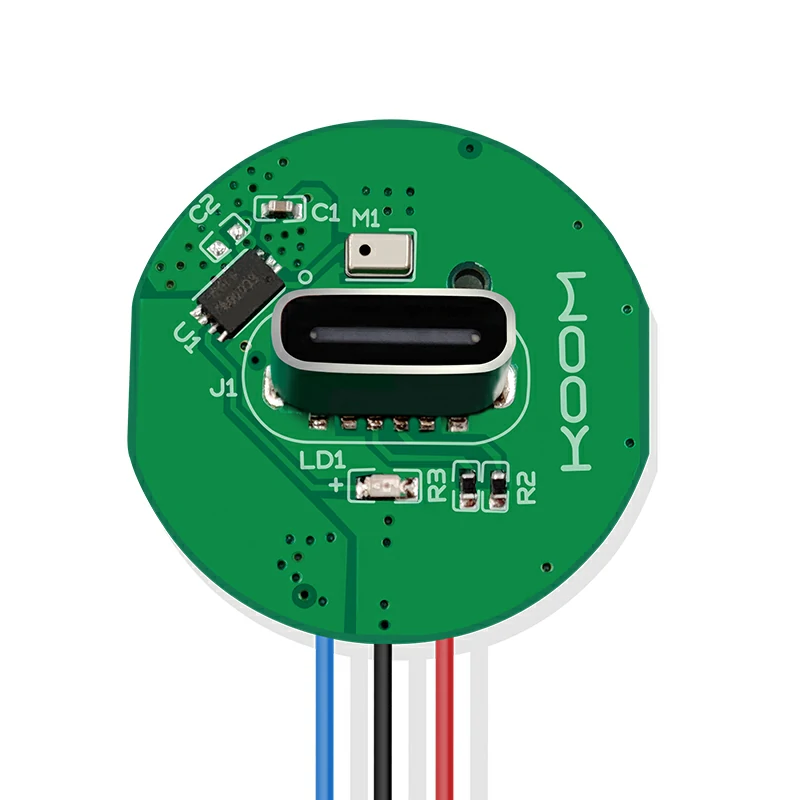

(2) Charging Management Module:

- Integrated charging control circuitry provides multiple charging modes, including trickle charging, constant current charging, and constant voltage charging.

(3) Battery Protection Function:

- Implements trickle charging to protect the battery when the lithium battery voltage drops below 7V.

- Transitions to high-current charging when the battery voltage reaches 2.7V or above.

- Enters constant voltage charging mode when the battery voltage approaches 4.2V to prevent overcharging.

(4) Multiple Protection Modules:

- Built-in undervoltage lockout (UVLO), temperature protection (OTP), overcurrent protection for the AT drive port, short circuit protection (SCP), and more to effectively prevent issues such as low voltage, high temperature, short circuit, and overcurrent, ensuring the safety of the battery and device.

(5) LED Status Indication:

- The LED light adopts professional IC design and is controlled through a PWM module, simulating the operation status of an electronic cigarette, providing users with information about the device’s operation and current status.

(6) Supports Various Charging Devices:

- Supports AC-DC and USB Type-C charging devices, among others.

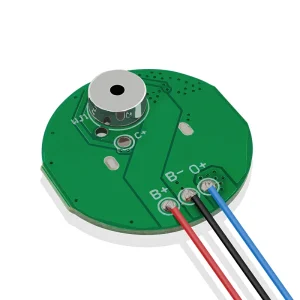

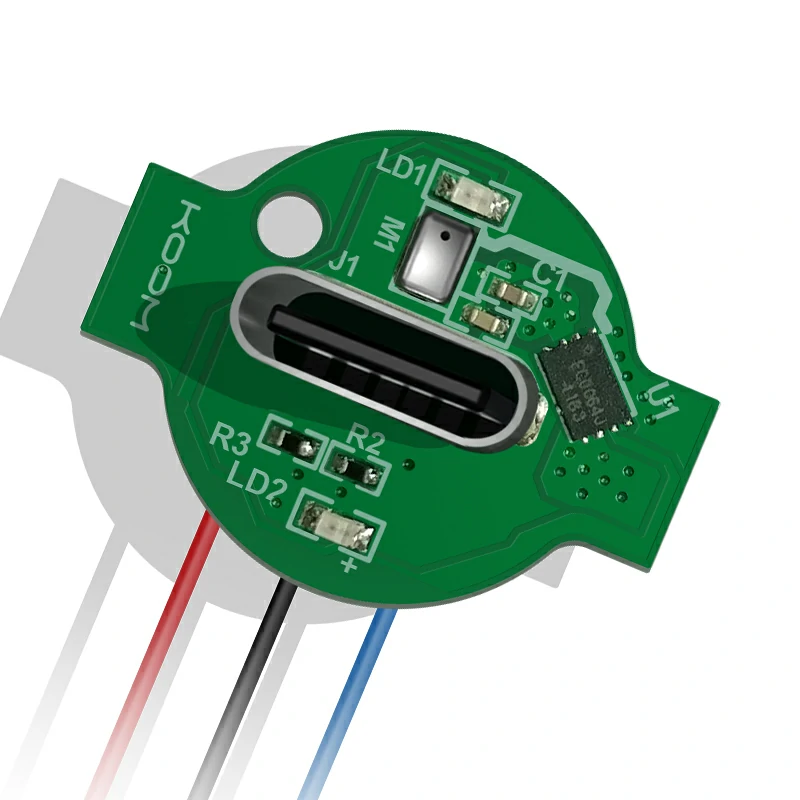

Hardware Architecture

Key Material Advantages

| Product Name | Features |

|---|---|

| E-cigarette ASIC Chip | Independently developed ASIC with powerful performance and high cost-effectiveness, widely used by major renowned brands |

| E-cigarette MEMS Sensor | Self-developed anti-logic MEMS with multiple patented technologies, excellent performance, good resistance to oil and corrosion, enhances product performance |

Frequently Asked Questions

- What is the atomizer in an electronic cigarette?

The atomizer is a crucial component of an electronic cigarette and serves as the main heating element. It is responsible for simulating the process of traditional smoking. Typically, it refers to the combination of a capacitor-type atomizer and a chip, which are fixed on the control board. They are connected to the heating coil and battery through circuits, enabling functions such as intelligent activation, charging management, status indication, and output power management.

- What are the components of an electronic cigarette control board?

The control board (PCBA) of an electronic cigarette generally consists of multiple key components and electronic elements. These components work together to enable various functions of the electronic cigarette, including the main control chip, battery, airflow sensor, LED indicator lights, charging management module, temperature sensor, connection lines and plugs, heating elements, among others.

- What are the common faults of an electronic cigarette control board?

The control board of an electronic cigarette may experience various faults or malfunctions that can affect the performance and safety of the device. Some common issues include battery problems, airflow sensor issues, heating element failures, main control chip malfunctions, charging management problems, LED indicator issues, circuit connection problems, temperature control failures, and more. If you encounter any of these issues, please contact our professionals for assistance.

Reviews

There are no reviews yet.